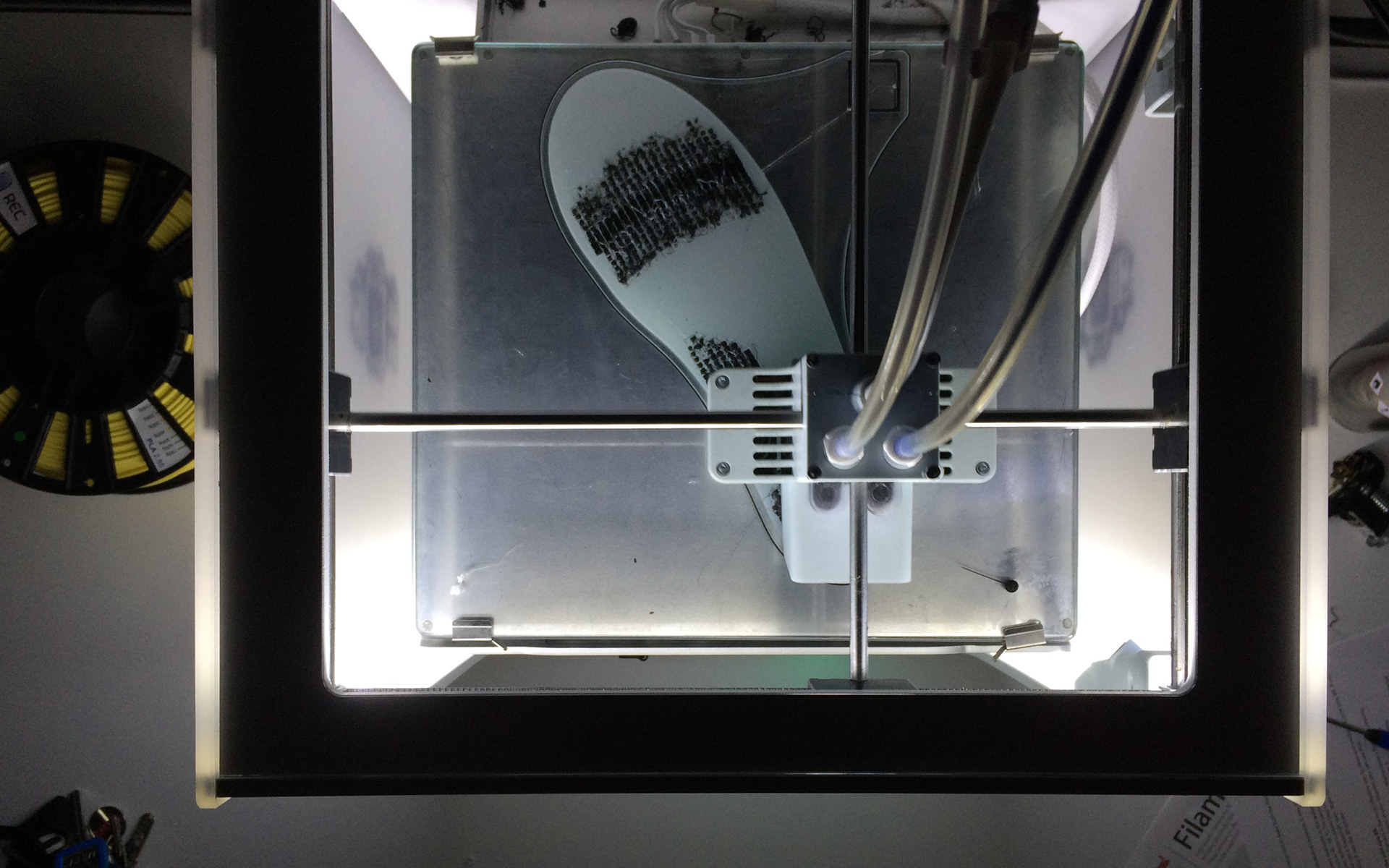

The project "FROM ADDITION TO PRODUCTION" explores the possibilities of rapid prototyping as a manufacturing process.

Generative design practices and rapid prototyping technologies open up new scope for design and business opportunities that have not existed in traditional manufacturing until now. Although 3D printing cannot compete with mass production in many areas (especially in terms of production speed and cost), there are areas where 3D printing is superior to conventional manufacturing methods. Three-dimensional composite materials, for example, not only have the potential to revolutionize the assembly and manufacturing of products, but also offer much greater design freedom. Mass customization, lightweight construction, wearables, adapted medical technology or healthcare products are further examples that demonstrate the potential of digital manufacturing beyond model making. This presents designers with different challenges than before, because flexible production demands equally flexible design solutions.

Generative design practices and rapid prototyping technologies open up new scope for design and business opportunities that have not existed in traditional manufacturing until now. Although 3D printing cannot compete with mass production in many areas (especially in terms of production speed and cost), there are areas where 3D printing is superior to conventional manufacturing methods. Three-dimensional composite materials, for example, not only have the potential to revolutionize the assembly and manufacturing of products, but also offer much greater design freedom. Mass customization, lightweight construction, wearables, adapted medical technology or healthcare products are further examples that demonstrate the potential of digital manufacturing beyond model making. This presents designers with different challenges than before, because flexible production demands equally flexible design solutions.

Winter semester project 2017-2018 // Supervisors: Natalia Echeverri Pinto and Marc Schömann // Students: Bettina Braun, Andreas Grzesiek, Elisa Holzer, Daniel Horie, Shuhan Luo, Fabian Schöfer, Yulia Stern, Steffen Strehl, Robin Thannberger // Photos: Marc Schömann